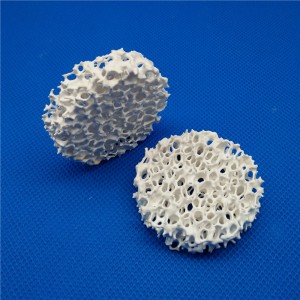

Alumina Ceramic Foam Filter rau Molten aluminium alloy pom

Alumina Ceramic Foam Filter rau Molten aluminium alloy pom

| Qhov Loj (mm) | Dimension (hli) | Pouring tus nqi (kg / s) | Lim muaj peev xwm (ton) |

| 178 * 178 * 50 | 7 * 7 * 2 | 0.2-0.6 hli | 5 |

| 228 * 228 * 50 | 9 * 9 * 2 | 0.3-1.0 | 10 |

| 305 * 305 * 50 | 12 * 12 * 2 | 0.8-2.5 hli | 15 |

| 381 * 381 * 50 | 15 * 15 * 2 | 2.2-4.5 | 25 |

| 430 * 430 * 50 hli | 17 * 17 * 2 | 3.0-5.5 | 35 |

| 508 * 508 * 50 | 20 * 20 * 2 | 4.0-6.5 | 45 |

| 585 * 585 * 50 | 23 * 23 * 2 | 5.0-8.6 | 60 |

| Khoom siv | Alumina |

| Xim | Dawb |

| Pore ntom | 8-60 ppi |

| Porosity | 80-90% |

| Refractoriness | ≤1200ºC |

| Khoov zog | > 0.6 Mpa |

| Compression zog | > 0.8 Mpa |

| Ntim-qhov hnyav | 0.3-0.45g / cm3 |

| Thermal shock resistance | 6 zaug / 1100ºC |

| Daim ntawv thov | Aluminium, Aluminium alloys thiab lwm yam Non-ferrous alloys |

1. Decontaminate cov melting hlau kua

2. Simplified rooj vag system

3. Txhim kho cov qauv metallurgical ntawm cov castings

4. Txo imparitied ntawm cov castings

5. Txhim kho casting zoo npaum li cas

6. Txo cov casting sab hauv re-oxidation tsis xws luag

7. Txo qhov deg tsis xws luag tom qab machining ntawm cov castings

1.Increased Fluidity

Kev tshem tawm ntawm kev suav nrog ua rau cov hlau ua kua dej ntau dua, ua rau cov pwm ua kom yooj yim dua, cov qauv cam khwb cia zoo dua, thiab zoo dua nyias ntu castability.

2. Txo Pwm thiab Tuag Hnav

Kev tshem tawm cov kev suav nrog thiab lwm cov khoom tsis yog hlau los ntawm cov yaj yuav txo cov kev tuag thiab pwm-hlau sib cuam tshuam, uas degrades pwm nto thiab kev pab cuam lub neej.

3.Longer Tool Life

Oxide thiab intermetallic inclusions tsim "cov tawv nqaij" uas ua rau cov cuab yeej puas hauv machining thiab ua tiav cov haujlwm.Filtration txo cov cuab yeej hnav thiab ua kom cov khoom tsim tau.

4. Tsawg qhov tsis lees paub

Inclusions nucleate porosity, tsim kua muag kub thaum lub sij hawm solidification, ua rau nto defects uas zoo li mar, thiab feem ntau txo txhua yam khoom.Hauv ntau qhov xwm txheej, pom kev txiav tawm tsis lees paub los ntawm qhov ua rau zoo li xoom.Kev txhim kho hauv cov txiaj ntsig tau ze li 100% thiab txo qis kev tsis lees paub rau ntawm lossis ze li 0% yog qhov tshwm sim.

1. Xuab zeb casting

2. Plhaub casting

3. Tsawg-siab tuag casting

4. Permanent pwm casting

5. Tuav thiab hloov tshuab